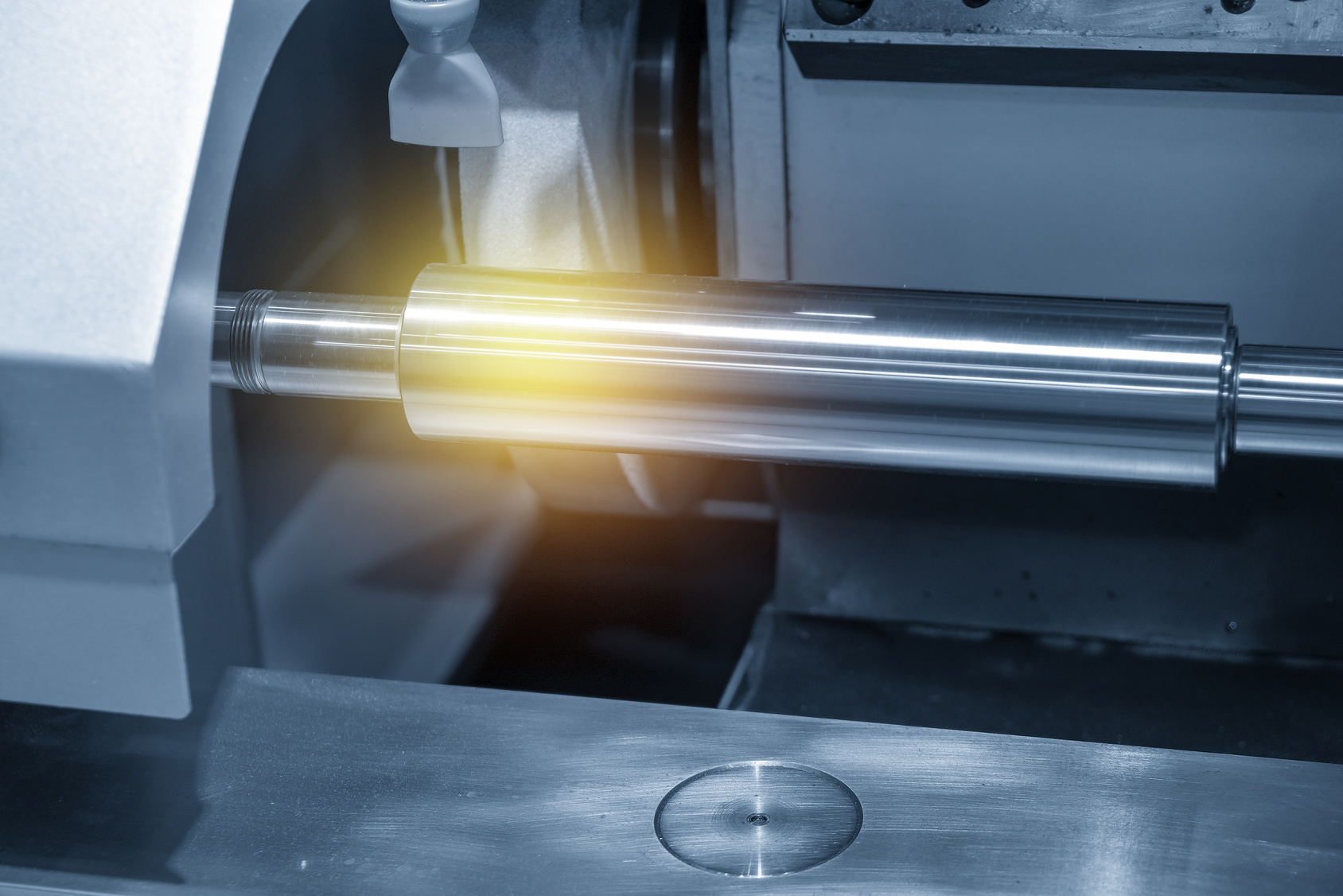

GRAINDING OF SHAFT

OPTIONAL FEATURE

- BEST PRODUCTS

- BEST SELL IN ALL OVER MARKET PLACES

- AFFOREDEBLE BEST PRICES

- BEST MATIERAL

- BEST RATING IN CUSTOMERS

- CUSTOMER SATISFACTION OF THIS PRODUCTS

TECHNICAL SPECIFICATION

| PRODUCTS DESCRIPTION: |

|---|

Grinding of a shaft is a precision machining process used to improve the surface finish, achieve tight tolerances, and remove any imperfections or material from a shaft. Heres an overview of the key aspects involved: Purpose: Surface Finish: To achieve a smooth surface finish and reduce surface roughness. Dimensional Accuracy: To ensure the shaft meets specific dimensional tolerances. Roundness: To correct any deviations from perfect roundness. 2. Types of Grinding: Cylindrical Grinding: For external cylindrical surfaces, where the shaft is rotated and ground using a cylindrical grinder. Centerless Grinding: For shafts where the material is fed between two wheels (a grinding wheel and a regulating wheel), and the shaft is ground without being mounted between centers. Surface Grinding: If the shaft has specific flat surfaces that need to be ground. 3. Grinding Process: Preparation: Clean the shaft and ensure its properly mounted on the machine. Grinding Wheel Selection: Choose the appropriate grinding wheel based on the material of the shaft and the desired surface finish. Setup: Align the shaft correctly on the grinding machine to ensure accurate grinding. Grinding: The shaft is ground using the rotating grinding wheel. The process may involve multiple passes to achieve the desired dimensions and surface finish. Measurement and Inspection: Regular measurements are taken during the grinding process to ensure that the shaft meets the required specifications. 4. Considerations: Material of Shaft: Different materials require different grinding wheel types and parameters. Grinding Wheel Specifications: Includes grit size, bond type, and wheel hardness, which affect the grinding efficiency and surface finish. Coolant Use: Coolant is often used to reduce heat buildup and improve surface finish during grinding. 5. Applications: Automotive: For crankshafts, camshafts, and other precision components. Manufacturing: For various machinery components requiring precise tolerances. Aerospace: For components that need high precision and smooth finishes. |