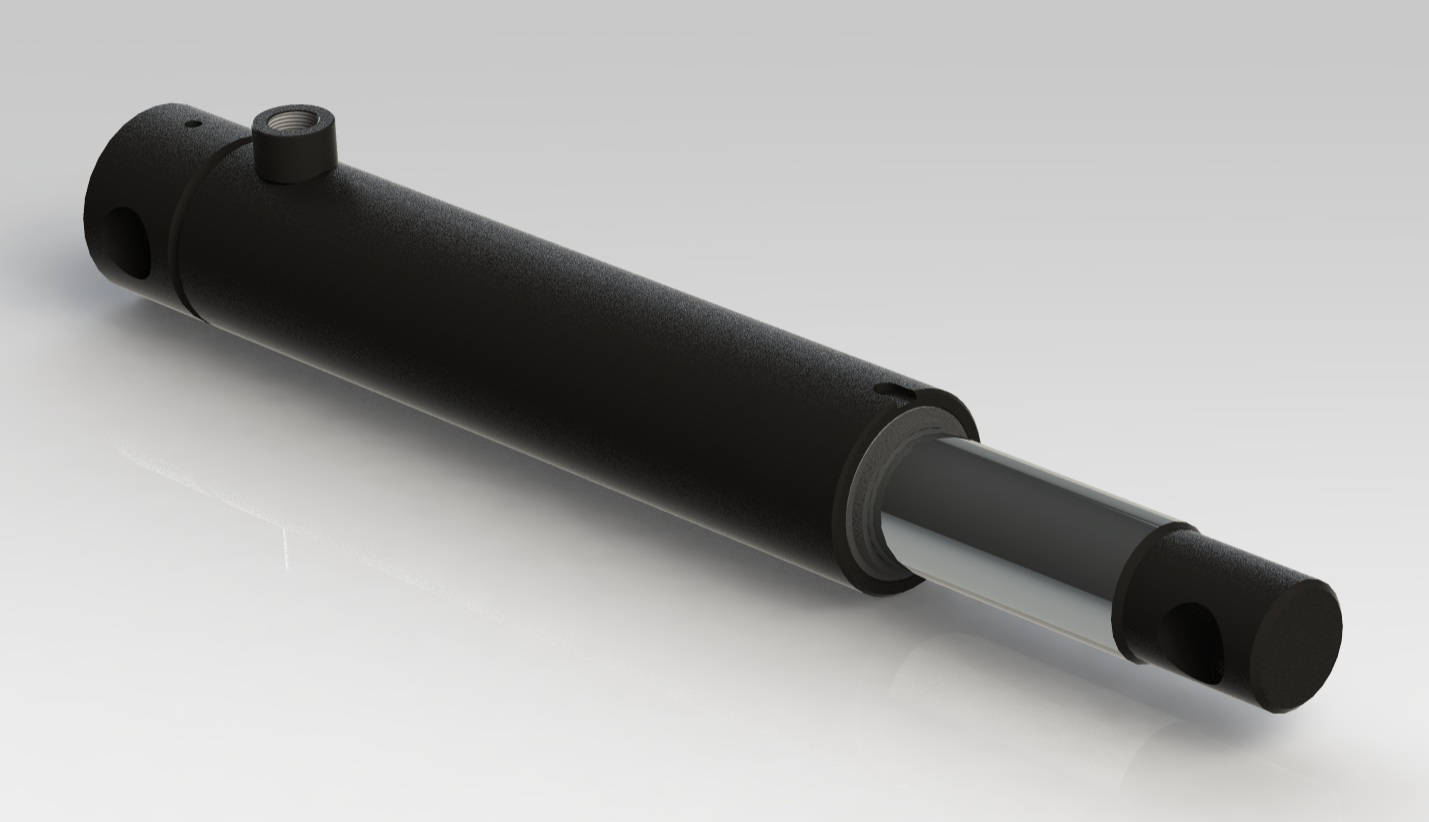

SINGAL ACTING HYDRAULIC CYLINDER

OPTIONAL FEATURE

- BEST PRODUCTS

- BEST SELL IN ALL OVER MARKET PLACES

- AFFOREDEBLE BEST PRICES

- BEST MATIERAL

- BEST RATING IN CUSTOMERS

- CUSTOMER SATISFACTION OF THIS PRODUCTS

TECHNICAL SPECIFICATION

| PRODUCTS DESCRIPTION: |

|---|

A single-acting hydraulic cylinder is a type of hydraulic actuator that converts hydraulic pressure into linear motion. Here's a quick rundown of its key features and how it works: Key Features: Single-Acting Design: It has one port for hydraulic fluid entry, which pushes the piston in one direction. The return stroke is typically achieved through an external force, like a spring or gravity, or by using an external mechanism. Piston: Inside the cylinder, a piston moves back and forth. Hydraulic fluid pushes the piston in one direction, while the return movement happens differently compared to double-acting cylinders. Simple Construction: Generally simpler and less costly than double-acting cylinders because it only requires one port and has fewer components. Limited Force Application: Effective for applications where force is needed in one direction, like in lifting or pushing applications. How It Works: Hydraulic Fluid Inlet: When hydraulic fluid is pumped into the cylinder through the inlet port, it pushes the piston out of the cylinder. Piston Movement: As the fluid enters, it creates pressure that moves the piston along the cylinders length. Return Stroke: The return stroke is not powered by hydraulic fluid but by an external force, such as a spring, or by the loads own weight, depending on the design. Applications: Lifting: Used in applications where lifting force is needed, like in some types of lifts or presses. Pushing: Common in applications that involve pushing an object or surface, such as in clamping devices. |